13 May 2024

The practical guide for safety in additive manufacturing

Insight

This document aims to provide essential safety guidelines for additive manufacturing, with a particular focus on Fused Deposition Modeling (FDM) 3D printing, which is the most commonly used 3D printing technology and covers the widest range of applications.

This guide has been collaboratively crafted with Alveo3D, a preeminent authority in additive manufacturing safety, to offer dependable and cutting-edge advice.

While FDM printing is widely used and accessible, it is common for 3D printer manufacturers to neglect incorporating effective safeguards against potential risks. This shortcoming, often justified by a desire to reduce production costs to lower prices, obscures the existing dangers. The proliferation of research and articles on the subject testifies to this reality.

As an example, BambuLabs experienced several incidents in just a few months, due to software bugs that activated printers without human intervention. User testimonials report problems related to malfunctions of the A1 model's print bed, leading to overheating of the power cables and, in some cases, combustion of the surrounding plastic.

We classify these hazards into two main categories: the major risks and the minor risks.

The major risks are mainly related to the noxious fumes generated during the heating and printing process of the filament, which become present as soon as the nozzle is activated.

As for the minor risks, they include thermal hazards (burns, risk of fire), mechanical hazards (equipment movement) and data security, which is often underestimated. These risks are considered less critical because they are more specific.

Protection against the harmful emissions:

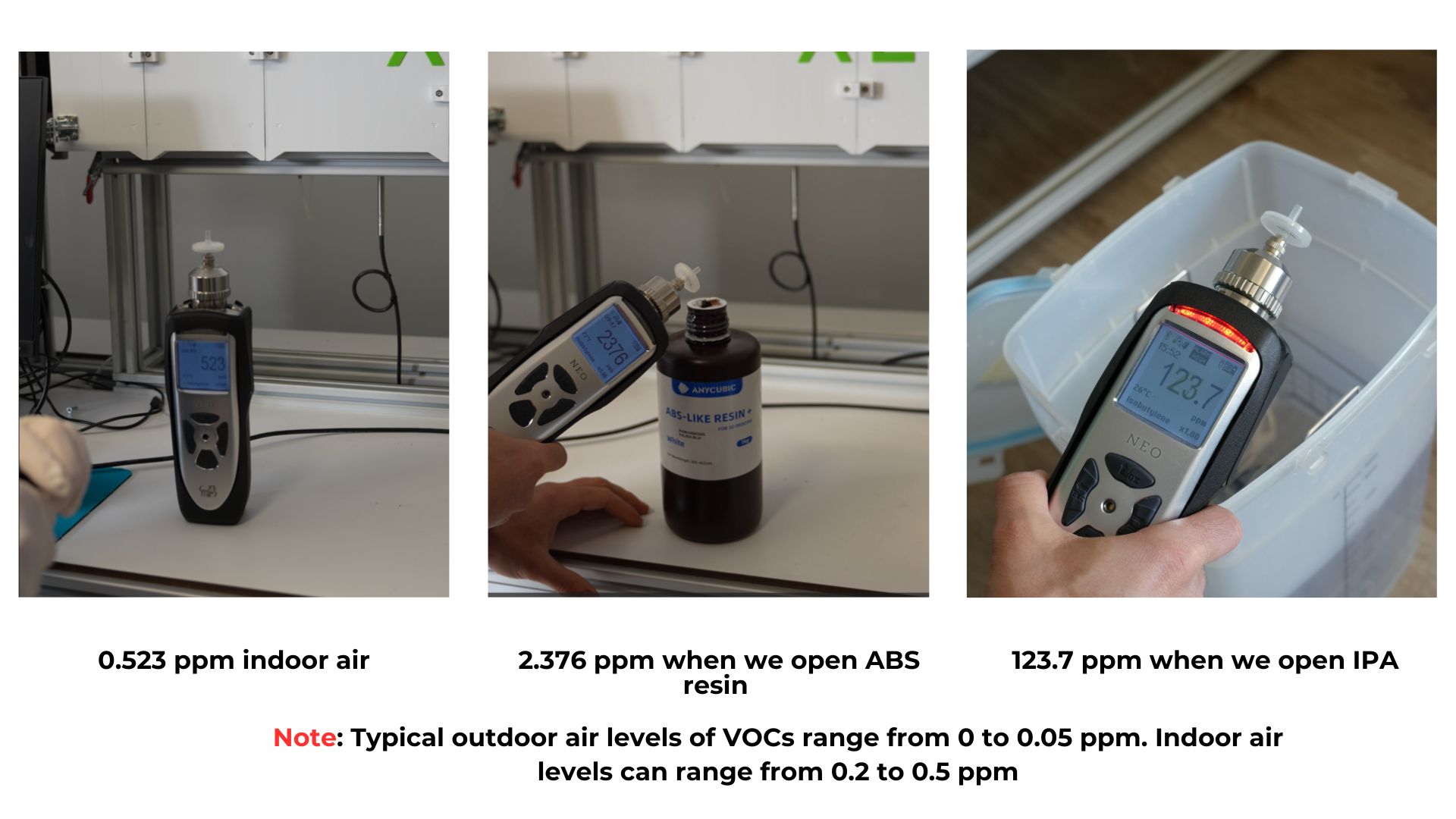

Numerous researches have highlighted the presence of polluting emissions and their potential toxicity to health when 3D printers are used. To minimize exposure to these emissions, it is crucial to implement adequate and effective measures.

To minimize exposure, it is advisable to place the 3D printer in a well-ventilated space. Prevention experts recommend regularly ventilating homes or workplaces several times a day. This precaution is very important in environments that may contain atmospheric pollutants; therefore, it is essential to avoid small enclosed spaces in favor of larger areas, allowing for better dispersion of pollutants.

Reducing exposure time is crucial, especially during periods of nozzle temperature elevation, such as during filament changes and the initial stages of 3D printing.

The analyses conducted by Alveo3D laboratories have revealed a significant increase in the production of nanoparticles, which are extremely fine, when the nozzle reaches its optimal operating temperature and during filament replacement. It is also crucial to consider that transitioning from one type of filament to another can result in an abnormally high quantity of particles.

For example, if transitioning from PLA filament (low emissivity) to ABS (high emissivity), the remaining PLA residues in the nozzle may be exposed to unusually high temperatures, leading to their combustion and consequently an excessive release of particles for a brief period.

When adequate ventilation for 3D printers isn't feasible, employing an enclosure, as advised by the INRS, along with an effective filtration system, confines emissions during printing, ensuring safety.

Enclosures help isolate emissions. However, if the filtration system recycles air inside the enclosure, it's crucial to check its airtightness. Most filtration systems draw air out of the enclosure, eliminating the need for a perfect seal. However, it's important to maintain lower air pressure inside the casing to prevent polluted air from leaking through its seals.

It is therefore not advisable to deactivate filtration to increase the temperature inside the printer enclosure. It is preferable to regulate the flow rate by adjusting the fan speed, thus ensuring adequate pressure management.

To select an appropriate filter, it is essential to consider two components: a HEPA filter of at least grade 13 certified according to the EN1822 standard, and activated charcoal.

The HEPA filter is very effective at capturing particles that are larger than 300 nm. Although standards do not certify its effectiveness for particles smaller than 300 nm; the study by Runcheng Fang, Afzaal Nadeem Mohammed, Jagjit Singh Yadav, and Jun Wang, entitled "Cytotoxicity and Characterization of Ultrafine Particles from Desktop Three-Dimensional Printers with Multiple Filaments", published on 22 August 2023, reveals that the majority of particles emitted measure less than 100 nm. It is therefore important to test the filter chosen for particles below 200 nm to guarantee its effectiveness.

Activated charcoal is effective in absorbing volatile organic compounds (VOCs), capturing a broad spectrum of these compounds and helping to maintain their concentrations below hazardous thresholds. However, once the activated charcoal becomes saturated, it allows all VOCs to pass through. Therefore, it's important to regularly replace the filter to ensure continuous protection.

To further reduce risks, it is preferable to allow the filtration system to operate until the printer bed cools to a temperature close to that of the ambient air. This ensures safe access to the printed object.

Taking into account the preventive measures mentioned previously, the use of personal protective equipment (PPE) is generally not required.

However, when conducting post-processing operations such as sanding, painting, or gluing, the use of appropriate PPE (such as gloves, a respirator mask, and safety goggles) is strongly advised.

The thermal risk refers to the dangers that can cause burns or fires, which may result directly from the high temperature of certain components (such as the nozzle or print bed) or an electrical malfunction of the device.

It is imperative never to touch the nozzle during printing and to wait for the bed to cool down before handling it.

Regarding electrical risks, it’s essential to ensure that the power terminals are properly fixed and positioned correctly on the electronic board. Regularly checking for any signs of abnormal burning around the connector of the heated bed and the nozzle is also recommended.

Installing a smoke detector in the room where the printer is located is an additional safety measure. Additionally, by incorporating an automatic extinguisher into the safety setup, you enhance protection further. However, it's important to select a model equipped with a heat-triggered mechanism, releasing an inert gas like Novec, to prevent damage to the electronic equipment.

Mechanical risk is omnipresent when using any machine, including 3D printers. This type of risk arises from physical interaction with the moving components of the device, whether it be moving parts, tools, or even the ejection of materials in solid or liquid form.

Accidents can take various forms, ranging from crushing to shearing, cutting, trapping, dragging, confinement, shocks, or falling objects. These incidents not only compromise the safety of the operator but can also cause irreversible damage to the machine itself.

In order to effectively counter these risks, it is recommended to take several precautionary measures. Operators must make sure to secure their hair and loose clothing to avoid any risk of being drawn in by moving parts.

Before any intervention on the machine, it is crucial to stop the printing or put it on pause to avoid any contact with hot or moving components. Adequate training on safe handling and regular maintenance of the printer can greatly contribute to reducing these risks.

In this digital era, data protection becomes increasingly important, especially with the rise of 3D printers equipped with advanced connectivity and artificial intelligence. These devices, capable of connecting to the internet for various services (remote updates, sending print files, camera monitoring, AI error analysis), introduce a new type of risk: intellectual property theft.

This threat is particularly concerning for users handling critical or confidential files, whether their own innovative projects or the sensitive data of their clients.

While convenient for certain functionalities, communication through the manufacturer's cloud requires heightened vigilance regarding the confidentiality and security of transmitted data.

To ensure the security of this information, it's recommended to limit cloud functionality whenever possible, especially when working on sensitive projects. Additionally, opting for printers offering direct connectivity options that bypass external servers can be a more secure solution for some users.

In short, 3D printing in the digital age necessitates a strong focus on data protection. By adopting proper security practices, users can minimize risks and safeguard their valuable files.

Operators and 3D printers users must adopt a safe behaviourIn conclusion, adopting a safety strategy in FDM additive manufacturing involves several key elements:

These actions form a solid foundation for ensuring safety when using FDM 3D printing technologies. It should be emphasized that for professionals, compliance with local and international regulations in force is essential.

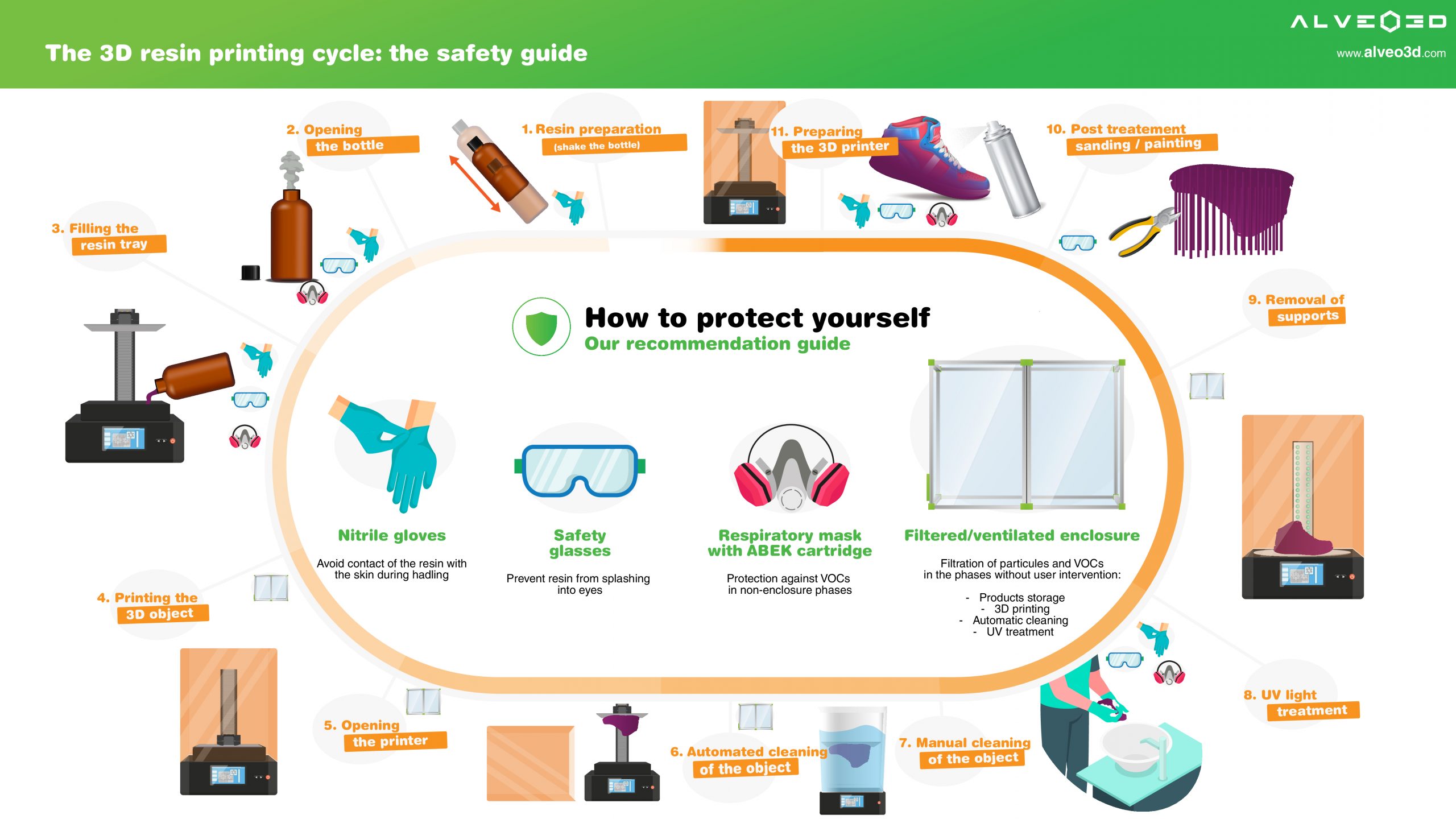

These regulations may require the adoption of additional safety measures to ensure a safe working environment. Furthermore, it is important to note that other 3D printing technologies, such as those using liquid resins, present unique safety challenges. These technologies therefore require prevention strategies and safety equipment adapted to their specific risks.

Comments